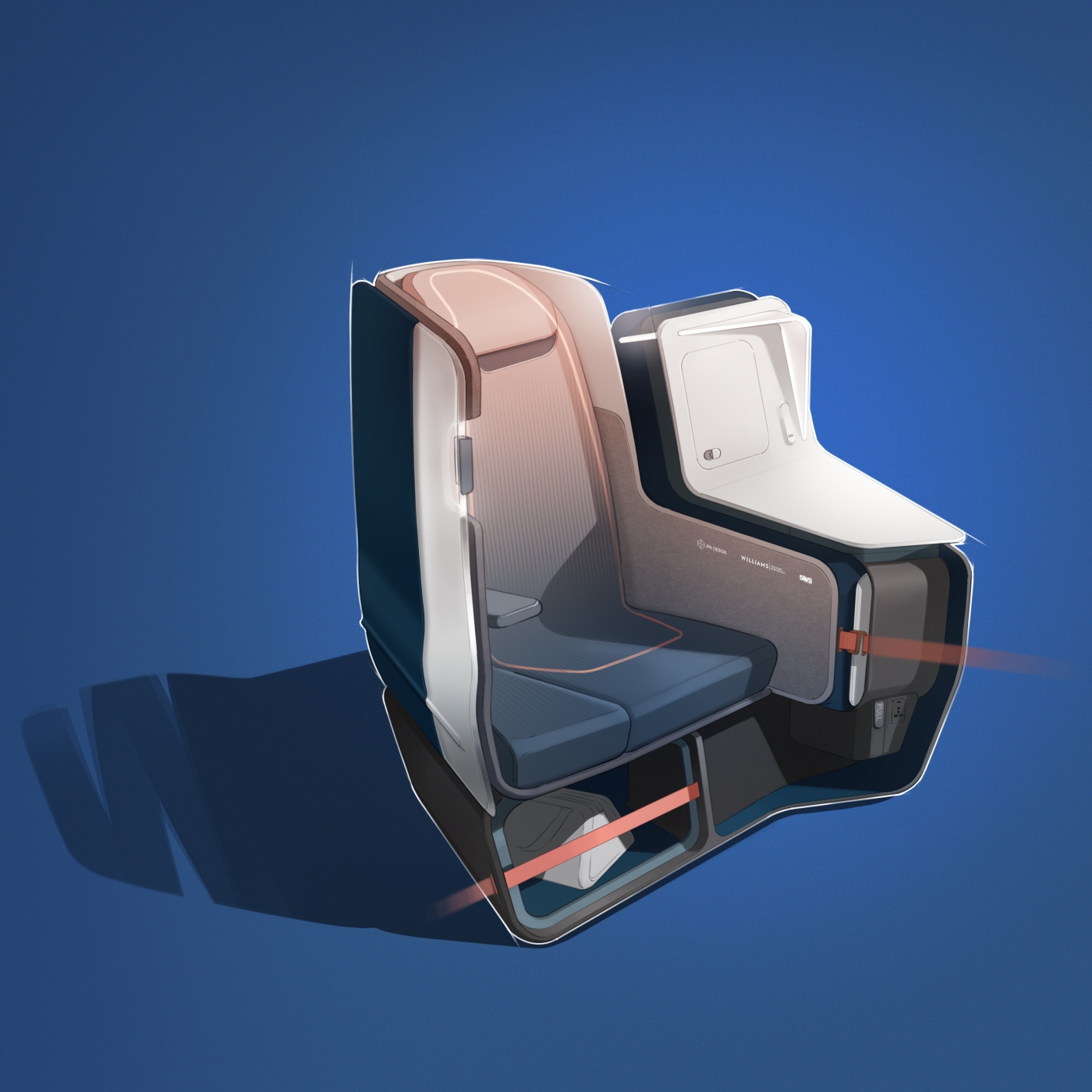

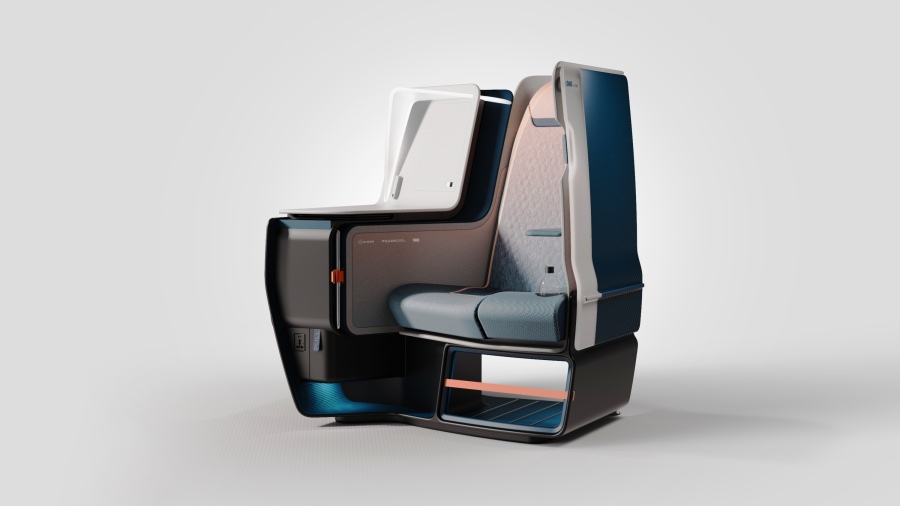

A little while ago, JPA Design announced a new type of Business Class seat, which on the surface may look like just another seat, but thanks to its partnership with Williams Advanced Engineering and SWS, the skin-deep appearance is anything but. Not only does the product learn from current design trends, it embraces lightweight technology, and also reflects the industry’s desire to be more sustainable.

Interestingly, Airtek is actually a UK government funded project. In partnership with the UK’s Aerospace Technology Institute, the project sought to bring together world-class expertise in design, engineering, manufacturing, material sciences and aviation certification.

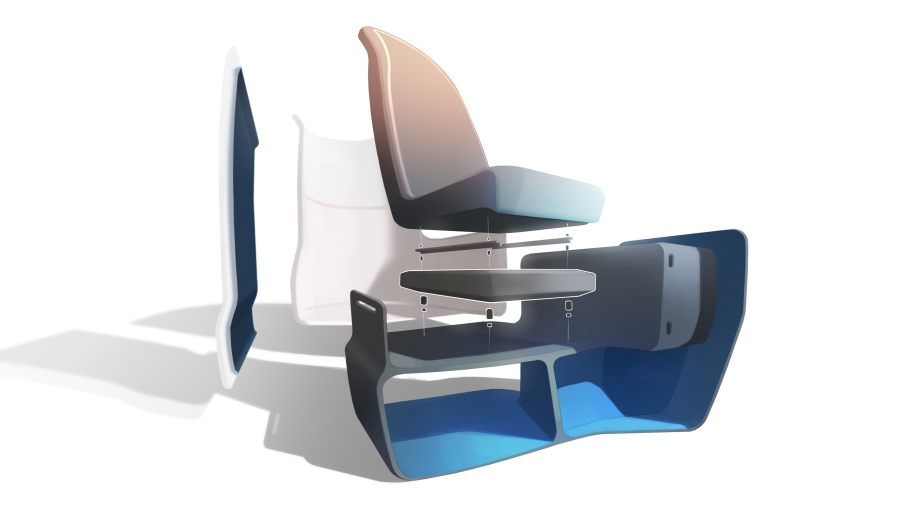

The secret sauce to this seat is the fact it’s built on monocoque principals. It’s no surprise to see Airtek utilising such a structure, as JPA also created Singapore Airlines’ latest business class seat that also featured the same manufacturing technique which allows for lighter weight and increased strength. Think how strong a simple egg’s shell is when it’s whole, that’s the beauty of monocoque.

However, JPA Design sought to maximise the opportunity, by ensuring that every space was considered to ensure maximum storage and passenger space. It’s this efficiency that is of real interest, as this seat design approach allows for a whole range of new possibilities across all cabin classes. For those in economy and especially premium economy classes, this means that we could see a new wave of seat designs in the future.

However, JPA Design sought to maximise the opportunity, by ensuring that every part of the seat was considered to ensure maximum storage and passenger space. It’s this efficiency that is of real interest, as this seat design approach allows for a whole range of new possibilities across all cabin classes. For those in economy and especially premium economy classes, this means that we could see a new wave of seat designs in the future.

“Although not currently working on economy class, the design, engineering and certification approach demonstrated on the business class seat is very transferrable to other areas of the cabin, such as economy seating, galleys and storage, and indeed we are keen to explore these in subsequent projects,” states JPA Design.

As the structure of the seat is so different and new to the aviation industry, the certification process basically has to start again, and as such the design and certification development phases are being run in parallel, allowing these requirements to be built in from the outset.

But why look to create a new seat, and is it really lightweight? Well according to JPA there’s an approximate 10% saving in seat weight, which will stack up on ASK calculations. But historically lighter seats have had a negative psychological impact. We notoriously associate lightweight, with flimsy, uncomfortable solutions, however the advanced technology at play has mitigated those concerns. In fact, JPA have set their stall that the Airtek will give customers more comfort, while giving airlines improved sustainability, reliability, cost savings and production efficiencies to boot.

And most of this is true. Considering the sheer volume of moving parts in a traditional business class seat, the reduced part count will make the seat easier to maintain and more reliable.

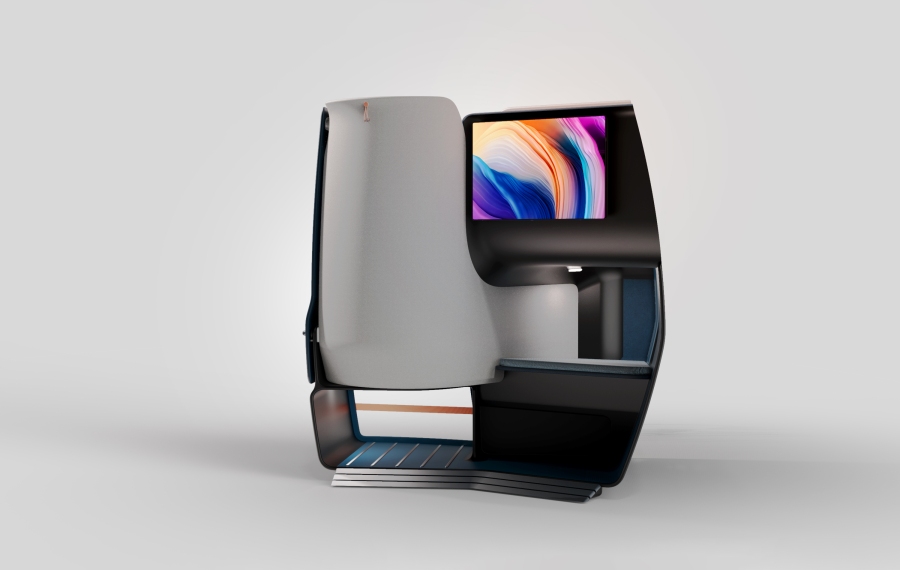

But to passengers who don’t really care about such things, there are the usual comforts associated with a reverse herringbone seat. There’s obviously the fully flat bed and usual work surfaces and large TV, but the seat also allows for under seat storage, removing the requirement for overhead bins, and the launch concept showcases the desire to use contemporary lightweight hi-tech fabrication, making passengers feel they are more or less in a gym shark showroom (no bad thing!).

We applaud the design concept, and collaboration between both Williams Advanced Engineering and JPA Design to not just create a seat that looks good, but actually goes some distance in trying to solve issues that airlines face by having such a product as part of their fleet.

As for future narrow-body aircraft? “The weight savings of Airtek are a perfect fit to benefit airline operations by reducing fuel burn and increasing mission range. Airtek is based on a flexible set of design principles and technologies that can be adapted for various applications and airframe types, and we are certainly targeting Airtek’s modular technology to the narrow body market.”

While it isn’t announced if there is a launch customer, we do know that the consortium has been supported by selected development partners from the commercial aviation industry including airlines and seats suppliers, all under NDA, of course.